The NPUST Department of Mechanical Engineering has been hosting its special industry-university partnership program for five years now; and for its next offering another 27 students are excited to join the ranks. Last year at this time, a special signing ceremony was planned to formalize the relationship between NPUST, several vocational high schools, several businesses and the students who would be taking part in the cooperative program. And although the pandemic changed the plans slightly, the contracts were all sent out and the students were all able to present the signed copies to the businesses when reporting for their first day as interns.

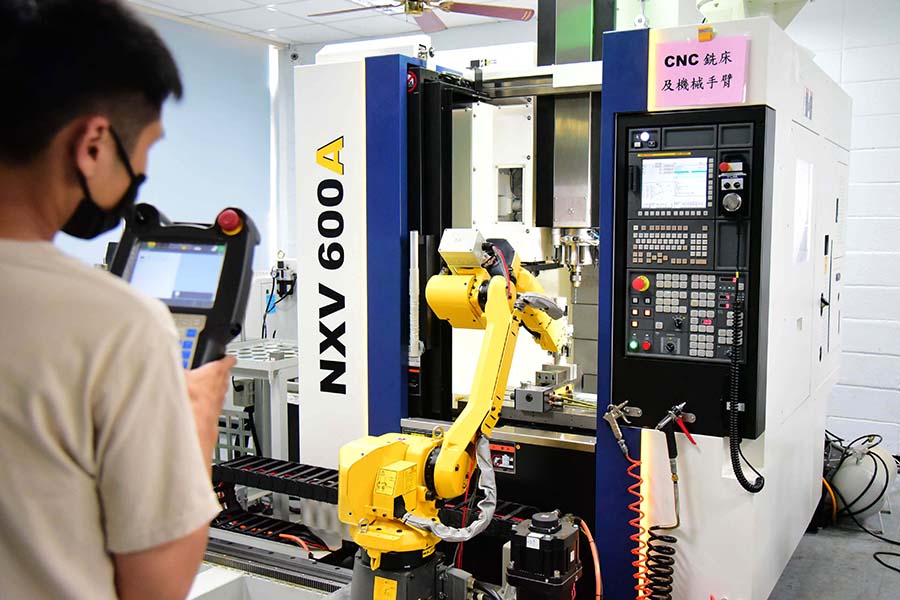

The Department of Mechanics created the class on precision machining in coordination with a Ministry of Education project. Through the partnership, students begin learning about mechanical engineering related subject matter in high school, then proceed to a four-year program at NPUST while simultaneously participating in paid internships at a cooperating manufacturer. Mondays through Thursdays, the students spend their day at one of the professional businesses, working as a paid employee and learning on the job. Fridays and Saturdays are then spent at the university, in the classroom studying theory. Presently, there are 67 students taking part in this “learn by doing and do while learning” model, and they are each positioned at one of six of the participating companies. The businesses are happy with the model that allows students to learn as they work and immediately start applying the knowledge they acquire in the classroom to their day to day tasks.

The Department of Mechanical Engineering has been cooperating with the Ministry of Education’s 3+4 Project for Academic-Industry Cooperation (3yrs vocational high + 4yrs technical university) since 2016. From setting the regulations and designing the curriculum to evaluating industry partners and coaching the participating teachers, a lot of planning and coordination was needed to get the program off the ground. The results, however, have been worth it; and they have created a situation that has left students, parents, and businesses with a real sense of satisfaction.

This summer, the second class of the special program will graduate. Yet, with the increasing number of students enrolling each year, by next semester there will be a total of 80 students interning with the partner companies as they work their ways through school. Although the epidemic has affected many things, orders have kept coming for the six partnering manufacturers, which is why each of them is eager to see more new students come in.

The model of learning has offered benefits to all the participants—reducing the financial burden of students, connecting businesses with bright young employees, and strengthening the relationship between academia and industry. And as NPUST cultivates more young talent and works to connect them with professional manufacturers, the manufacturers are also turning to the university to develop closer cooperation on technology for such things as machining and aerospace parts manufacturing. Ultimately they are closing the gap between theory and practice, and in doing so, creating an all-around win for those involved – a true affirmation of the effectiveness of the NPUST approach to education.